JC Casting is a Kneader Blade manufacturer and supplier in China. We can produce many Kneader Blade Types for different Applications.

The kneader is mainly composed of six major parts: the kneading part, the base part, the hydraulic system, the transmission system, the vacuum system and the electric control system.

The kneading part is composed of a cylinder block, paddle shaft, wall plate, cylinder head, and so on.

The kneader blade is the part that comes into direct contact with the material. The material is kneaded by the paddle.

So, it is necessary to introduce the common kneader blades to you.

Kneader Blade Types

There are four main types of kneader paddles: fishtail kneader blade, cutting kneader blade, Z kneader blade, and Σ kneader blade.

The following JC Casting technicians will introduce these types of blades one by one.

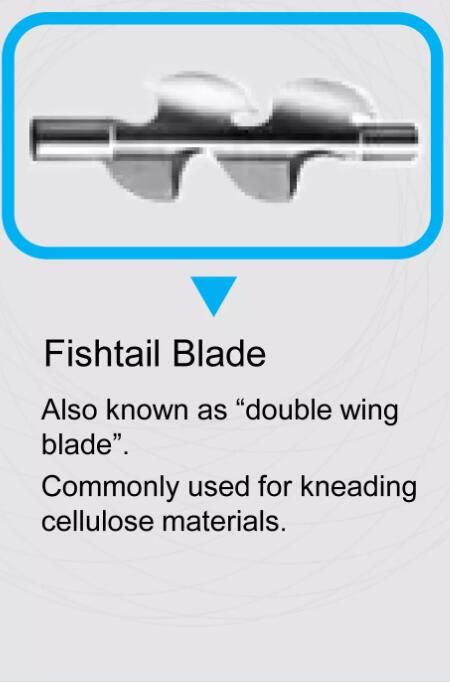

1. Fishtail-type kneader blade

As the name suggests, the fishtail-type kneader blade is a kneader blade whose appearance is imitated by the fishtail.

Such blades are suitable for kneading operations on cellulosic substances.

2. Cutting-type kneader blade

The cutting blade is one of the toughest paddles available. It is suitable for the kneading operation of ultra-high viscosity substances under the condition of high power and heavy load.

When using cutting-type kneader blades, two paddles are mostly arranged in a tangential line.

Applicable materials for cutting-type kneader blades: rubber, iron oxide, magnetic recording materials, etc.

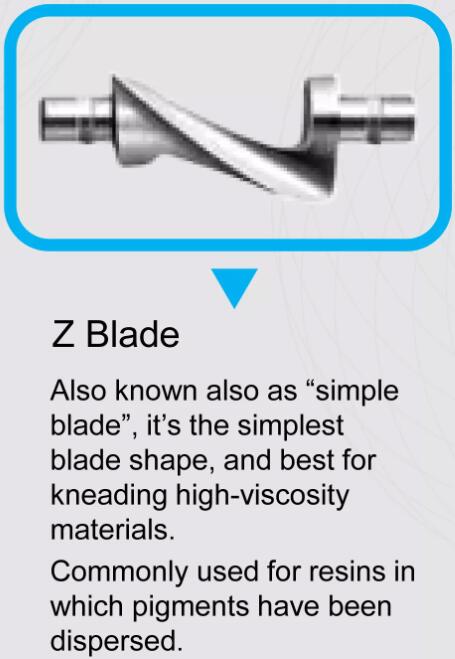

3. Z-type kneader blade

The z-type kneader blade is also called a simple kneader blade. Its shape is simple.

It is used to disperse and knead the pigment in the resin in the case of high viscosity.

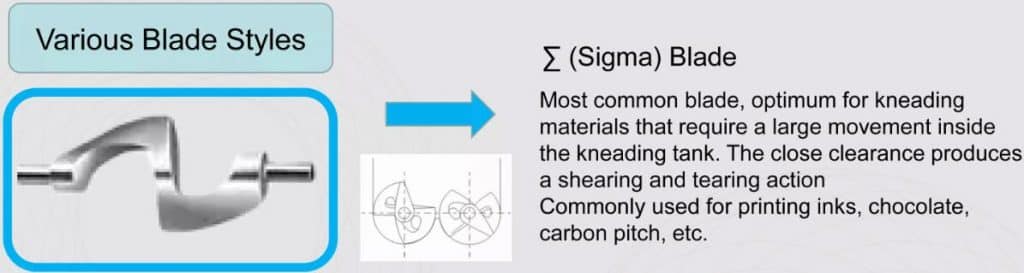

4. Σ-type kneader blade

The Σ-type kneader blade is the most common type. It is also called Sigma impeller or Sigma Blade. It is suitable for the kneading operation of substances with large movement in the kneader tank. A side-by-side tangential differential arrangement is adopted. Tone kneader blade speed is fast. Another speed is slow. So it generates shear force. Different paddle speeds enable the kneaded materials to be sheared quickly. So that the materials can be mixed evenly. Especially suitable for extrusion dehydration operations.

Applicable materials: chewing gum, chocolate, glass glue, sealant, hot melt glue, butyl glue, manhole cover, and carbon material.

PS:

What is the Kneader?

The kneader is a special mixing and stirring equipment. Usually, a side-by-side tangential differential device is used, that is, one impeller is fast and the other is slow. To generate shear force, different impeller speeds can make the mixture cut quickly. The material can be mixed evenly. Since most of the materials stirred by the kneader are high-viscosity materials, they are also high-density materials. Such as rubber-like viscous plastic materials. The resistance encountered by the kneader blade during the mixing process is relatively large. To get uniform mixing, the kneader needs to be equipped with a high-power motor for the kneader blade, which consumes a lot of energy.

Kneaders are widely used in the mixing, kneading, crushing, stirring, vulcanization and repolymerization of high viscosity and high elastic-plastic materials.

The kneader has the advantages of uniform stirring, no dead angle and high kneading efficiency.

Kneader Blade manufacturer

JC Casting is a Kneader Blade manufacturer in China. Most of our Kneader Blade has been manufactured by the lost wax investment casting process. We have supplied many Kneader blades for China kneaders. If you have any inquiries or purchasing needs for Kneader, we would like to introduce the China trustable kneader manufacturers!