Investment Casting Process

What is the Investment Casting Process? We can produce top-level investment castings in a variety of dimensions and shapes. In our foundry, the Investment casting process is operated with the most advanced technology in China. In the whole process, all-metal alloys are available, we can customize investment castings according to your material specifications. Even material compositions are feasible for production. To ensure the best quality, quality control will be done in each investment casting process.

Here are the whole steps of the investment casting process in our foundry:

Step 1: Tooling Making

Tooling Making is the first step for investment castings.That is the basic to achieve precision products. Such tooling or pattern will be precision machined by our CNC center. Regularly speaking,the tooling cost will be charged from our customers for the sample order of a new product is placed. But it is just one-off paid. We will not ask for this fee from second orders.

Step 2: Wax Injection and Pattern Assembly

After casting patterns is finished, we will make wax pattern. The wax pattern is obtained by injecting wax into the pattern. We will get a model with the same dimensions of desired products. Then, we will repeat the injection job for more wax patterns. Then assemble these wax patterns onto the sprue. Finally hang these pattern assemblies in the room temperature for drying.

Step 3:Shell Coating

In Shell coating, the pattern assembly will be dipped into a ceramic slurry and coated with a refractory material. Repeating this process several times until getting a certain thickness and strength. Then, the ceramic shell is finished and then put into an atmospherically controlled environment until be dried.

Step 4: Dewax

Putting the shell in a steam autocalve and rapidly heated. So that the wax will be melt and run out through the gate and pouring up under high temperature. The ceramic shell molds must be fired to burn out the last traces of pattern material and to preheat the mold in preparation for casting. Usually in the range of 1600-2000 degrees Fahrenheit. That is why investment casting also called “lost wax casting”.

Step 5:Casting or Pouring

After dewaxing, we will melt the steel or aluminum ingots into liquid status. Then pour the liquid metal into the spruce. Then cool it under room temperature for a moment. Casting is the key step in the whole investment casting process.

Step 6: Shell Removing

After Cooling,Break the ceramic shell and cut the individual investment castings from the sprue. Then remove the excess metal from casting body by grinding.

Step 7:Heat Treatment

The heat treatment is usually done after finishing castings.The process can improve the mechanical properties of casting blanks. The main heat treatment processes are: Normalizing, tempering, annealing, hardening and tempering, carburizing. On the cost,heat treatment is additional. If you have heat treatment requirements,it will be cleared in advance and extra cost counted.

Step 8: Shot Blasting/Sand Blastin

To remove scales and achieve better surface finish, investment castings will be shot blasted or sand blasted by small steel balls.So all the foundries must be equipped with shot blasting machines.

9.Anti-rust Oil Painting & Surface Treatments

In avoid rusting, castings will be dipped into anti-rust water or oil. The other surface treatments can also be performed in this step like paint spraying, galvanizing.

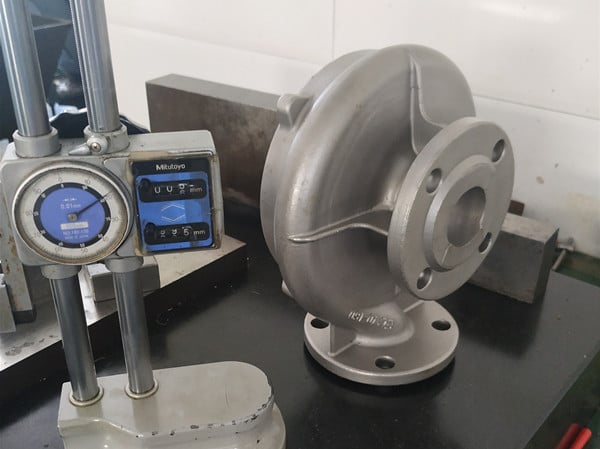

10. Quality Inspection

Inspection is also a step for investment castings quality control. Our QC will do dimensional inspection, 100% surface inspection, inner defects inspection and other inspection jobs according to requirements of products.Only after all the products inspections are qualified,we can delivery to our customers.

11. Package

Normally we pack investment castings with ploy bags, then put them into carton box and standard wooden cases.We can also provide custom package service according to customers’ requirements.