What is the difference between Silica Sol VS Water Glass?

Many people think of water glass and silica sol when saying the adhesive. These is the 2 adhesives widely used in precision casting. So what is the difference between silica sol and water glass? Now let’s learn it together.

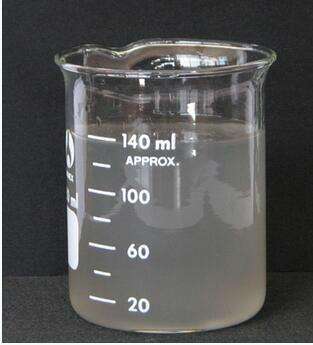

Silica sol characteristics

Silica sol is a dispersion of nano-sized silica particles in water or in a solvent. It is a colloidal solution, odorless and non-toxic. Since SiO2 in the silica sol contains a large amount of water and hydroxyl groups, the molecular formula of the silica sol is SiO2.nH2O.

Water glass characteristics

The water glass is in the state of sodium silicate solution. Also known as saponin. An aqueous solution of sodium silicate is commonly known as water glass. Sodium silicate is a colorless, slightly colored transparent or translucent viscous liquid in a system in which water is used as a dispersing agent. Solid sodium silicate is a colorless, slightly colored transparent or translucent glass block. The form is divided into liquid, solid, and water quenching. In theory, these substances are called “colloids.”

How to distinguish between silica sol VS water glass

1—–The characteristics of the two are different, as above.

2—– Different uses.

The main uses of silica sol are as follows:

1. Used as a binder for various refractory materials, featuring strong adhesion and high-temperature resistance (1500 ° C – 1600 ° C).

2. It is used in the coating industry to make the coating firm, and it can resist dirt, dust, aging, fire, and other functions.

3. For thin shell precision casting, it can make the shell type strong and the casting smoothness is high. It is better in shape than water glass. Instead of silicate molding, it reduces costs and improves operating conditions.

4. Silica sol has a high specific surface area. It can be used in catalyst manufacturing and catalyst carriers.

5. Used in the paper industry. It can be used as a cellophane release agent, a photographic paper pretreatment agent, a cement bag anti-slip agent, and the like.

6. Used as a sizing agent for the textile industry. It is used together with oil to treat the spinnability of wool and rabbit hair, reduce breakage, prevent flying flowers, improve yield and increase economic benefits.

7. Used as a silicon steel sheet treatment agent, a picture tube dispersant, a floor wax anti-slip, and the like.

The use of water glass is as follows: in chemical production.

1. It is used to make silica gel, white carbon black, zeolite molecular sieve, sodium metasilicate pentahydrate, silica sol, layered silicon, instant powdered sodium silicate, sodium potassium silicate, etc. Silicate products. It is the basic raw material of silicon compounds.

2. In the light industry, it is an indispensable raw material in detergents such as washing powder and soap. It is also a water softener and a preservative.

3. Used in the textile industry for dyeing, bleaching, and sizing

4. Widely used in the machinery industry for casting, grinding wheel manufacturing and metal preservatives, etc.

5. Used in the construction industry to manufacture quick-drying cement, acid-resistant cement waterproof oil, soil curing agent, refractory materials, etc.

6. Silicon fertilizer can be produced in agriculture

In addition, it is used as a silicon-aluminum catalyst for catalytic cracking of petroleum, a filler for soap, an adhesive for corrugated paper, a metal preservative, a water softener, a detergent builder, a refractory material and a ceramic raw material.

JC Casting is a Silica Sol investment Casting and Water Glass Casting manufacturer in China. Contact us here for more information about JC Casting, obtain a quote, or to discuss your water glass project requirements in more detail. Alternatively, please get in touch using the details below.

Contact:

+86 181 05467890

[email protected]