What is Steel Casting?

Steel casting is a casting form that involves different kinds of steel. Cast steel is being used when cast iron cannot provide the level of strength needed. This is formed by pouring molten steel into a mold. The castings will be molded according to what it needed to be produced. The process of steel casting is being performed only by metalwork experts.

Steel is a versatile metalwork material. However, it is difficult to melt, unlike iron. With this, a true expert must do the procedure. These days, steel casting is being used in different industries like electronics, food processing, and construction.

Properties of Cast Steel

Cast steels carry different properties. The physical properties may change when heat or other chemicals are incorporated into the process. The cast steel will be carefully selected and processed so it will produce the needed output.

- Toughness

Cast steels can endure stress. To adjust the toughness of cast steels, one may alloy metals and apply heat.

- Hardness

Steel casting is abrasion-free. It has high levels of hardness that even scratches will not be seen in the material.

- Strength

It is difficult to deform cast steels by force. This is how strong it is. This also determines its durability.

- Wear Resistant

Cast steels are wear and tear-resistant. It can resist friction and frequent use. Its wear resistance levels make it perfect for components that will be severely used.

- Rust Resistant

This allows the material to be corrosion-resistant. Despite constant use, cast steels have a high tolerance of elements that can cause corrosion.

- Ability to be Welded

This is the edge of cast steels over other castings. It can be welded to create shapes and forms needed without being damaged.

Advantages of Steel Castings

Steel castings are widely used in many industries. These are also used in household and commercial products. It has become popular and in-demand because of the advantages it provides.

- Reliable

Steel castings are reliable. With its strength and durability, the component produced will not easily give in to damage. It promises longevity to the industry it will serve.

- Economically Beneficial

The prices of cast steels are competitive in the market as compared to other castings. You can find reasonable rates but still get the same quality and durability that you are expecting from it.

- Design Flexibility

With steel castings, you can create even the most complex and unique shapes, designs, and forms you need. This is easy to form and deform if needed. The flexibility of cast steels is perfect for any industry that requires unique and durable castings.

- Adaptability

Cast steels can go through any processes needed. It can adapt well to different chemical compositions, heat, and other procedures required to produce a component.

Types of Cast Steel

Cast Steel has many types. According to chemical composition, cast steels are categorized into two general groups. These are carbon cast steels and alloy cast steels.

Carbon Steels

Carbon steels are special types of steel. Because it has a higher concentration of carbon. It also has types of low carbon steel,medium-carbon steel,high-carbon steel. With this, it provides a lot more benefits to its users. Carbon steels are stronger and more durable as compared to ordinary steels. It is more resistant to stress but may still break if exposed excessively. This type of cast steel is being used in industries like construction, automotive, and many others.

Generally speaking,low carbon steel ZG15 has a higher melting point, but poor casting performance. It is only used to manufacture motor parts or carburized parts.

Medium carbon steel ZG25~ZG45 has comprehensive properties higher than all kinds of cast iron. That is a high strength, excellent plasticity, and toughness. Therefore, it is suitable for manufacturing parts with complex shapes, high strength, and toughness requirements. Such as train wheels, forging hammer stands and anvils, rolls, and high-pressure valves. It is the most widely used type of carbon cast steel.

The high carbon steel ZG55 has a low melting point. Its casting performance is better than that of medium carbon steel. But its plasticity and toughness are poor. It is only used to manufacture a few wear parts.

Alloy Steels

Alloy steels are formed when elements that are composed of metals and non-metals are joined with carbon steels. These are used in many industries such as mining, automobiles, road construction, and many more. Alloy steels are not just for big components, they are also used to make small and basic household equipment.

According to the total amount of alloying elements, alloy cast steel can be divided into two categories: low alloy steel and high alloy steel.

(1) Low alloy cast steel. my country mainly uses manganese series, manganese silicon series and chromium series. Such as ZG40Mn, ZG30MnSi1, ZG30Cr1MnSi1, etc. Used to make parts such as gears, hydraulic press working cylinders and hydraulic turbine rotors. And ZG40Cr1 is commonly used to manufacture important stressed parts such as high-strength gears and high-strength shafts.

(2) High alloy cast steel. It has special properties such as wear resistance, heat resistance or corrosion resistance. Such as high manganese steel ZGMn13. It is a kind of anti-wear steel. Mainly used to manufacture parts used under dry friction working conditions. Such as the front wall and teeth of the grab bucket of excavators, the crawler tracks of tractors and tanks, etc. Chromium-nickel stainless steel ZG1Cr18Ni9 and chromium stainless steel ZG1Cr13 and ZGCr28, etc. High corrosion resistance to nitric acid. Mainly used in the manufacture of chemical, petroleum, chemical fiber, food and other equipment parts.

In comparison, while both types of steel are useful and in demand, they are the total contrast in terms of their properties. Alloy steels are more corrosion resistant than carbon steels. But its strength and durability are inferior to carbon steel. There are many contrasting properties and elements between carbon steels and alloy steels. But in the end, both are highly useful for many industries and trades.

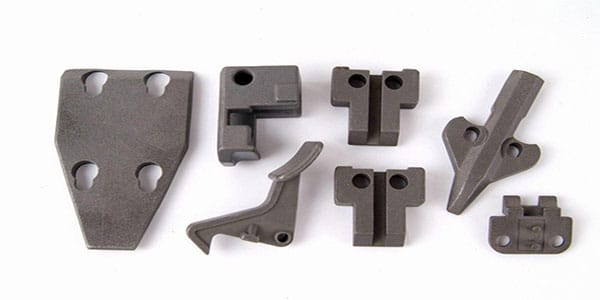

Applications of Steel Casting

Steel castings are efficient in many applications. Therefore, it has become in-demand in the market. Its popularity is still growing worldwide.

- Railway Locomotives

Many of the key elements in railway locomotives use steel castings. You may find them in components like side frames, wheels, couplers, and bolsters.

- Power Station Apparatus

Different components in thermal and nuclear power stations use steel casting to ensure durability and efficiency. The properties that cast steels possess make them a reliable component in this industry.

- Construction Equipment

Building and construction industry need tools and equipment that can withstand high stress and pressure. So, cast steels are perfect for making construction equipment and components such as wheels, load wheels, and many others.

- Mining Equipment

Mining is a fragile industry. Everything used in its operations needs to be durable and can offer safety to its workers. Steel casting is carefully used in creating the needed equipment for this industry.

- Aerospace Equipment

Steel castings have been used in different aerospace equipment even from way back. Some of the key components used in aerospace are made of cast steel such as engine brackets, brake support plates, and many others.

- Agricultural Machines

Many agricultural machines go through harsh conditions, and this makes steel castings very efficient.

Steel Casting Manufacturer and Supplier

JC Casting is a leading manufacturer and supplier of steel investment castings. Our company based in Dongying, Shandong, China has been providing the best products and services for their clients. Our products and services involve different materials, which include carbon steel, alloy steel, aluminum and so much more. We can produce castings for different industries like agriculture, construction, railways, and more. Any castings needed, JC Casting will surely provide in utmost quality and efficiency.

Why choose JC Casting? We have wide experience in providing casting needs of clients. Their client base continues to grow because of their best quality products and services. And best of all, JC Casting makes sure that the satisfaction of their clients is guaranteed and achieved.

For inquiries about steel investment casting products and services, you may call +86 181 05457890 or email them at info@investmentcastingpci.com.