This article will give in-depth information about aluminum investment casting so readers will learn what it is and its advantages.

Design engineers often face the dilemma of which casting to use for the products they need to produce. There are different casting types, processes, and materials to choose from. Most of the time, these professionals choose the one that is most efficient, economical, versatile, and holds high tolerances. Investment casting appears to be purposeful for many industries and businesses. Its capacity to create mold and forms so an end product will be produced helps in keeping industries and businesses productive.

Investment casting is widely preferred these days because of its capabilities to provide detailed and accurate components without the need to spend too much money, time, and resources. Many design engineers choose investment casting as it allows them to have the design needed in a precise manner. With the advancements of technology, experts can use different materials for investment casting, and among these is aluminum.

What is aluminum investment casting?

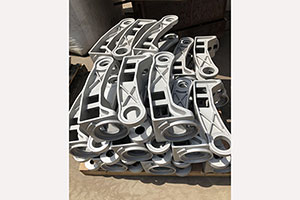

Aluminum investment casting is using aluminum in making an investment casting tool. To create complex designs, aluminum is melted, cast, and goes through a machine. It is a favorite material for casting because aluminum is easy to melt, making the process faster and easy to accomplish. More industries prefer aluminum investment casting because of its versatilities. Among the trades that choose this procedure include automotive, aerospace, military, agricultural, and many others. Industries hold a lot of reasons they choose aluminum investment casting.

Why Choose Aluminum for Investment Casting?

Many materials can be used for investment casting. The most preferred is metal. But what makes aluminum becoming a more popular choice these days? Here are some reasons.

- Aluminum helps in easily achieving the designs needed. It can create even the most complex designs and forms. This makes customization easy to create and complete.

- Production can also be done in a faster mode. Aluminum is easy to melt allowing more designs and forms to be made. Industries that need many parts produced in a small amount of time can rely on aluminum investment casting.

- Aluminum is strong and sturdy. It has the strength of metal, which makes it a reliable material for casting.

- This material is lightweight and cheaper. Despite its strength, it can easily be handled because its weight is not a struggle. It is also cheaper than compared to other materials used for investment casting.

- Investment castings made from aluminum are versatile and rust-resistant. This provides longer life and usage span. Aluminum allows manufacturers to produce many products. So, industries see aluminum investment casting a good value for their money.

Using aluminum in investment casting provides a lot of advantages. It can help industries in coming up with the most robust and purposeful investment casting for different products. With the aluminum investment casting around, industries and trades can have more options on which casting to choose. Aluminum is a material that provides different properties that can be useful for many products.

Beneficial Properties of Aluminum

- Excellent electrical conductivity

- Ductility

- Malleability

- High thermal conductivity

- Non-toxicity

Opting for aluminum investment casting can provide industries the best products they need for different purposes. Even the simplest products you use in your household could be produced using aluminum investment casting. Some products where aluminum is mostly used are:

- Cans

- Construction materials

- Window frames

- Kitchen utensils

- Power lines

- Household appliances

- Transportation parts

These are just a few that make use of aluminum for the casting. The molds created from aluminum investment casting can be useful in many industries and businesses. And because of its beneficial features, it is now becoming more popular in the market. Now that you know much about aluminum investment casting, can you imagine the processes involved in it? Well, to give you an idea, here are the procedures involved in investment casting using aluminum.

Processes of Aluminum Investment Casting

- Melt Aluminum

Melting aluminum can be fast and easy especially that there are already a lot of high technology machines and tools used. The molten aluminum will then be poured into a mold. This is to make the molten material follow the desired pattern.

- Die-Cast

This process will turn the molten aluminum into a steel die. It will go through machining and finishing so a precise aluminum mold will be formed.

- Permanent Mold Casting

This is to finish the mold for the product to be made. It will involve cores of metals or steel. It is important that the product molded is easily removed from the mold. This is when semi-permanent mold casting techniques are used.

- Sand Casting

This is the most versatile process in using aluminum for investment casting. Though this process is slow, it is more economical.

Industries these days are lucky to have better and useful machines so investment casting can be made easily. And now that aluminum investment casting is becoming more popular, more trades and businesses are looking into switching to this process. Though the other castings are also useful, many design engineers prefer the one that will fit perfectly with the product to be made. Aluminum’s versatility and strength make it a suitable material for any design molds and form.

Conclusion

With the need to create the tool, aluminum is easy to melt, machine, and modify. It makes the entire process fast to accomplish creating more end products more speedily. The popularity of aluminum investment casting makes it an in-demand process in many industries. With the versatility and other features of aluminum, it makes a good choice in making any complex forms and designs needed. Therefore, it has become a common choice among design engineers. Aluminum investment casting provides a lot of benefits and efficiencies to industries. Its purposes extend to different businesses, trades, and industries.

As the popularity and demand for aluminum casting increases, the population of providers also rise. This is a good thing for design engineers and industries as they can see a lot of options before making the final choice on which investment company to deal with. Keep in mind that reputation, efficiency, quality, and cost should be considered before choosing the provider for your aluminum casting. This is to get the best value and quality that you would want to achieve.