Aluminum Casting vs Steel Casting

Casting has become an important procedure in manufacturing. The casting products are used by many industries. Most of these products are being used by many people in their daily lives. With casting, even the most complex designs are available. There are no restrictions on the designs, shapes, and forms that can be made with the use of casting.

Many materials can be used in casting. These days, aluminum and steel are among the most preferred to be used. It is because these exude strength, durability, and appeal. When casting the products they need, many manufacturers rely on these two materials’ property

Both of them have advantages and disadvantages. Manufacturers still prefer the two because of their good properties. Comparison will help one know which one is better for a particular product.

There are many properties that one should look into when casting materials. Their choice will be based on the type of product to be made and what it needs to be efficient in its desired purpose.

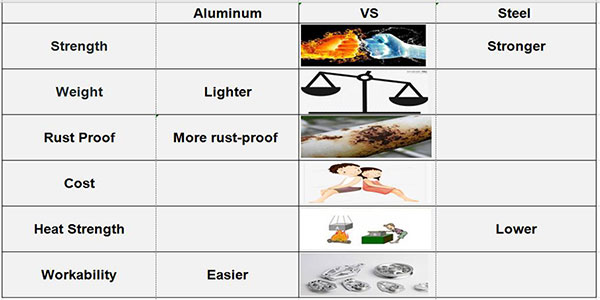

Here are the properties of aluminum casting vs steel casting.

Strength

In general, steel is stronger than aluminum. Though other metals are stronger than steel. It is still a good material if the product requires enough strength. It can be used in many applications and industries. Aluminum is also strong but appears to be inferior if compared to steel.

Weight

Aluminum has lesser weight than steel. If you are looking for a material that is strong but lightweight, aluminum will be your choice. Aluminum products offer a weight advantage as compared to those made of steel. Adding more elements to the aluminum casting improves its strength and stiffness. But still needs to maintain its weight-friendly property.

Rust Proof

Aluminum is more rust-proof than steel. Its corrosion resistance level is very high. That is why it is a preferred material especially in products that are used in moist and wet industries. Different types of steel show different levels of corrosion resistance. If you will use carbon steel, then expect it to rust easily. Stainless steel has high corrosion resistance. But if the product that you have to make needs to be rust-free, then aluminum casting can do the job.

Cost

The costs of both castings may vary. The aluminum casting and steel casting can be costly. Especially if they were made of good quality. The cost may rely on the type of product made, quality, and brand or manufacturer.

Heat Strength

Aluminum castings have low heat strength as compared to steel castings. Aluminum only requires a low temperature for it to melt. It easily melts with heat making it easy to use and create the products needed. But if the product will be used in a high-temperature environment. It is better to use steel casting.

Workability

Workability does not stop when the casting is made. It will still go through a lot of procedures to create the product needed. When it comes to workability, aluminum is easier to melt, so, more fluid and easy to pour into the mold. Aluminum castings are also easy to work on because it is less stiff than steel casting. Because of its strength and stiffness. There is a lot more effort needed when working on steel casting.

These properties will determine the type of casting to use for a particular product. Manufacturers are aware of these properties. They know exactly which one to choose.

Generally, both castings have their plus and minus points. But it is also clear that both are useful and efficient to produce strong and durable products needed by many industries.

Applications of aluminum casting vs steel casting

Aluminum casting and steel casting have a lot of applications. Many industries need products that are made from these castings.

Aluminum Casting Applications

· Aluminum casting can be used to make plane components. The aerospace industry has already been using aluminum castings even from way back. Because of their lightweight and strong properties.

· Automotive parts and supplies use aluminum castings. Such as water pump housings, oil pumps, transmission parts, connectors, and many more.

· This is used in making lighting fixtures. These products need the lightweight, strength, and durability properties of aluminum castings.

· To make agricultural equipment like crankcase housing, motor housing, and gearbox housing.· Aluminum castings can be used in making brackets for heavy-duty equipment

· To make golf equipment and products like brackets, golf ball warmers, handles, and golf clubs.

Steel Casting Applications

· Steel castings are used in making equipment and types of machinery for food processing and culinary. Such as 304 stainless steel castings. 316 stainless steel castings.

These casting products are more used in metal grinder parts, coffee machine parts, oven parts, and many more.

· Products used in cutlery and kitchen are also made of steel casting. Spoons, forks, knives, and others are a few of the things where steel casting is used.

· The marine industry relies on steel castings in making marine components and equipment.

· Used in making medical tools and supplies. Like surgical tools, operating room equipment, operating tables, stretchers, wheelchairs, and many more.

· To make pipe fittings.

· To make a vast of construction and building equipment, machines, and components.

Conclusion: Aluminum Vs. Steel Casting

There are a lot of things to consider before deciding which material to use for casting. Both aluminum casting and steel casting are efficient for any product it is intended to use for.

One may simply look into its properties and components before deciding. This is to choose the most appropriate casting to use for the product needed.

For inexperienced buyers, it is best to consult the experts first. This will bring you good advice on the best possible material to use.

There are already a lot of casting manufacturers and suppliers around. Consulting them will help you decide whether you should use aluminum casting or steel casting. Just make sure that you choose the casting company to deal with.

You have to choose one that is already reputable in this industry. This way, you can be sure that you are making the right choice of casting.

If you have any requirements for aluminum castings or steel castings, contact JC casting to get the best solutions. Email us at [email protected]